Latest Technologies in Steel Industry

Three steps form the foundation of the steel industry’s basic steel production processes: raw material preparation, ironmaking, and steelmaking. For certain purposes, all of these procedures can be completed using a wide variety of steel kinds. Since industrial production started in the late 19th century, steel industry fabrication techniques have substantially improved. Current methods still rely on the same basic principles as the original Bessemer Process, which reduced the amount of carbon in iron by using oxygen. In the ironmaking phase, lime, coke, and iron metal are melted in a blast furnace as crude feeds. Furthermore, the finished liquid iron still has 4-4.5 percent carbon and other contaminants that weaken it.

BOF (Basic Oxygen Furnace) and the more modern EAF (Electric Arc Furnace) are the two fundamental processes used in steelmaking. Essential shaping includes things like rods, tube rounds, hot and cold rolled strips, rails, and structural shapes. The steel then receives its final shape and characteristics by secondary processes like coating, heat treatment, surface treatment, and metal cutting.

Notwithstanding all of the difficulties facing the steel sector, including changing consumer preferences, unstable geopolitics, the effects of e-mobility, digitalization, etc., certain technologies offer more effective procedures, better-quality steels, environmentally friendly production, consistent quality, etc. Four technological advancements in the steel industry are as follows:

Different Methods in the Steel Industry

1. The ORC Technology

Thermodynamically heat changes to work in a cycle called Rankine Cycle and this system depends on the water gives around 85% of overall power generation.

The Organic Rankine Cycle has the same working principle as the Rankine Cycle but ORC depends on a turbo generator running. It transforms heat energy into mechanical energy and electrical energy at last. The difference is rather than creating steam from water, the ORC technology vaporizes a natural liquid. Therefore it provides a slower turn of the turbine, reduces pressure, and no abrasion of the metal parts and sharp edges. This system can produce enough power from waste up to 700 houses around. Also, the carbon footprint of the facilities from the steel industry decreases by about 10.000 tons of CO2 while removing the water need for cooling systems.

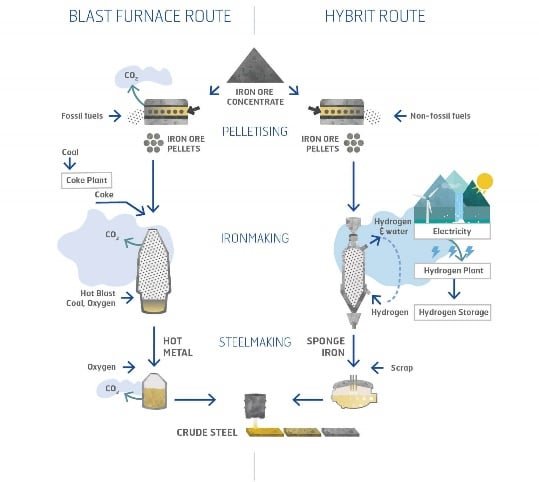

2. Hybrit Process

The collaborative task of three Swedish organizations, SSAB, LKAB, and Vattenfall started the project called ‘Hybrit’ (‘Hydrogen Breakthrough Ironmaking Technology’). The goal is to create zero-carbon in steel production beginning from 2020.

Conventional production of pig iron includes coke and iron ore to remove oxygen on the other hand this process releases to the atmosphere hazardous gas carbon dioxide. The mentioned new generation procedure utilizes hydrogen, which besides can remove the oxygen in the iron ore, yet the outcome is water vapor instead of carbon dioxide. Change existing procedures to remove characteristic conditions on petroleum products. In this way, the Hybrit process idea is totally becoming green steel.

The Hybrit process falls within several advancements that are the utilization of hydrogen as a decreasing agent, with the hydrogen being generated through electrolysis depending on sustainable power. From a natural point of view, the most significant benefit of this is the fumes from this procedure is water rather than carbon dioxide.

The products coming HDR (Hot Direct Reduction) process out is named DRI (Direct Reduced Iron) or “sponge iron) which is fed into BOF or EAF mixed with an appropriate amount of scrap, and further prepared into steel. In spite of the fact that this particular blend of procedures has not been executed at the business scale. A few of the individual segments are as of now broadly utilized in the worldwide steel industry. Numerous parts of the HDR/EAF arrangement have been tried and sent in modern settings but key difficulties still remain.

3. Jet Process

Particularly equipment and robotization have been improved and optimized within the most recent years to completely consent to real standards. One of the latest advancements for exceptional converters is the Jet Process. General proficiency of over half is come to and a wide scope of scrap rates can be handled in an exceedingly profitable way. An innovative way to amplify scrap and HBI (Hot Briquetted Direct Reduced Iron) rates in converter steelmaking.

The internal energy of the hot metal is discharged during the oxygen-blowing step make it conceivable to feed around 20% scrap converters. Providing external power allows to make the rate up to around 30%. This additional power usually can be given by electricity or coal.

The Jet Process is designed to take advantage of the chemical energy of coal more efficiently and cost-effectively in the converter. Scrap metal additions can be higher without external energy in this way. Also, the high adaptability of the system makes it easier to implement. Hypothetically, scrap charge rates from 0 to 100% are conceivable with this adaptable procedure. No coal addition is necessary up to 30% scrap charges. To increase the adaptability it is designed a modular converter which enables the fast installation of a conventional BOF converter base and an oxygen blowpipe, thereby enabling the converter to be quickly installed to operate as a typical BOF converter.

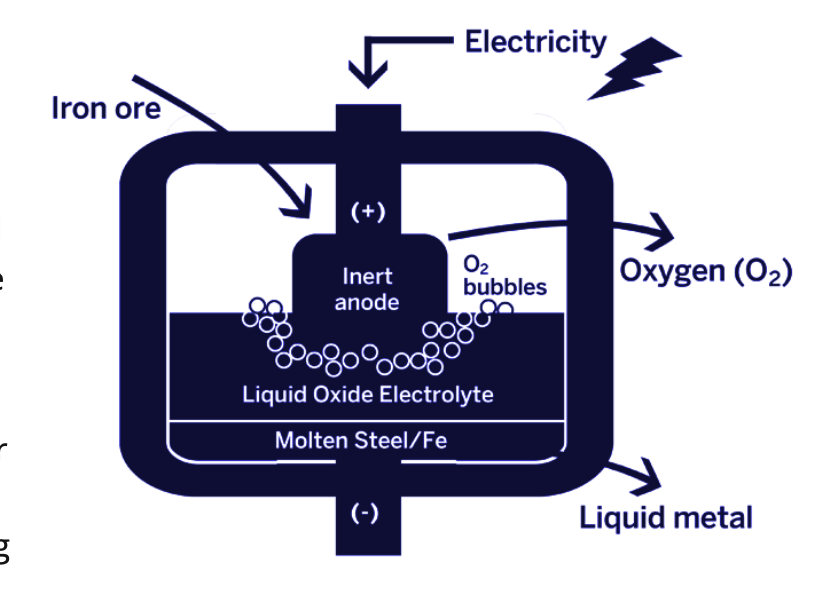

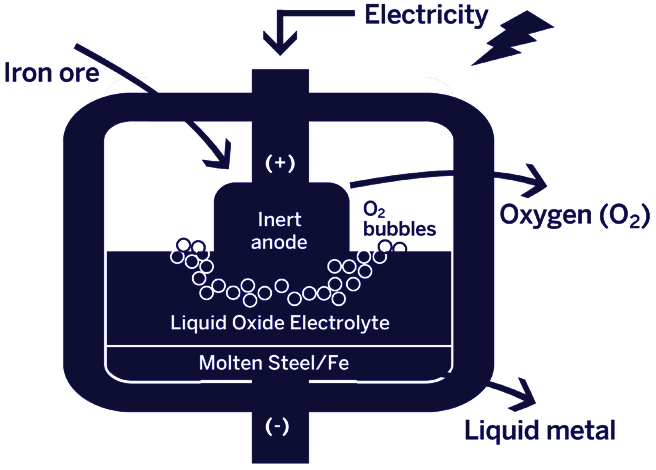

4. Molten Oxide Electrolysis

Molten Oxide Electrolysis is an unconventional electrometallurgical system that allows quick production of metal in the liquid state from oxide raw material. It promises considerable simplification of the whole process and essential energy need minimization. Molten Oxide Electrolysis has been proved to utilize anode materials which are graphite for use with ferro-alloys and titanium and iridium for use with iron. It is needed to overcome several challenges to produce metal without process carbon such as process temperature, corrosion of metals considering electrolysis conditions, and abrasion of refractory materials.

Still, it offers exceptional properties in terms of applicability to multiple metals as well as high-temperature operations to produce liquid metal. A review of the transport properties of molten oxides shows that an unprecedented yield can be predicted as a promising feature for tonnage production in the steel industry.

Molten Oxide Electrolysis advancements created at the Massachusetts Institute of Technology. Professor Donald R. Sadoway’s lab proved that it could be possible to produce emission-free steel by producing low-cost inert anode at the lab scale with help from NASA, the American Iron and Steel Institute, and the Deshpande Center at MIT. Looking at the state of the technology in electrode materials, it appears that quantitative design criteria for both cathode and anode continue to be developed.

If you want to learn more about steel industry and superiorities of steel as a product, you can read our other posts; https://yenaengineering.nl/5-cases-to-say-yes-to-structural-steel/